Sealing and Bolting Innovation:

TECHNICAL SOLUTIONS

Our engineers work tirelessly on the technical design of cutting-edge bolting equipment. Every bolt, nut, or tool that leaves our hands is meticulously crafted to deliver high performance and reliability. Our obsession with technical perfection ensures that the bolting equipment we develop can withstand the most rigorous and critical conditions in the industry

PROCESS AND METHODOLOGY

Our Tech Center is constantly developing new systems and improvements, addressing challenges, needs, and potential benefits identified in our industry, as well as responding to specific customer requests.

Mechanical Design

Conceptualization

Virtualization

Simulation and optimization

Manufacturing

Technical assistance

Best practice manuals,

procedures and training

Modeling and numerical simulations

Diagnose and problem solving

Load calculations, measurements and validation

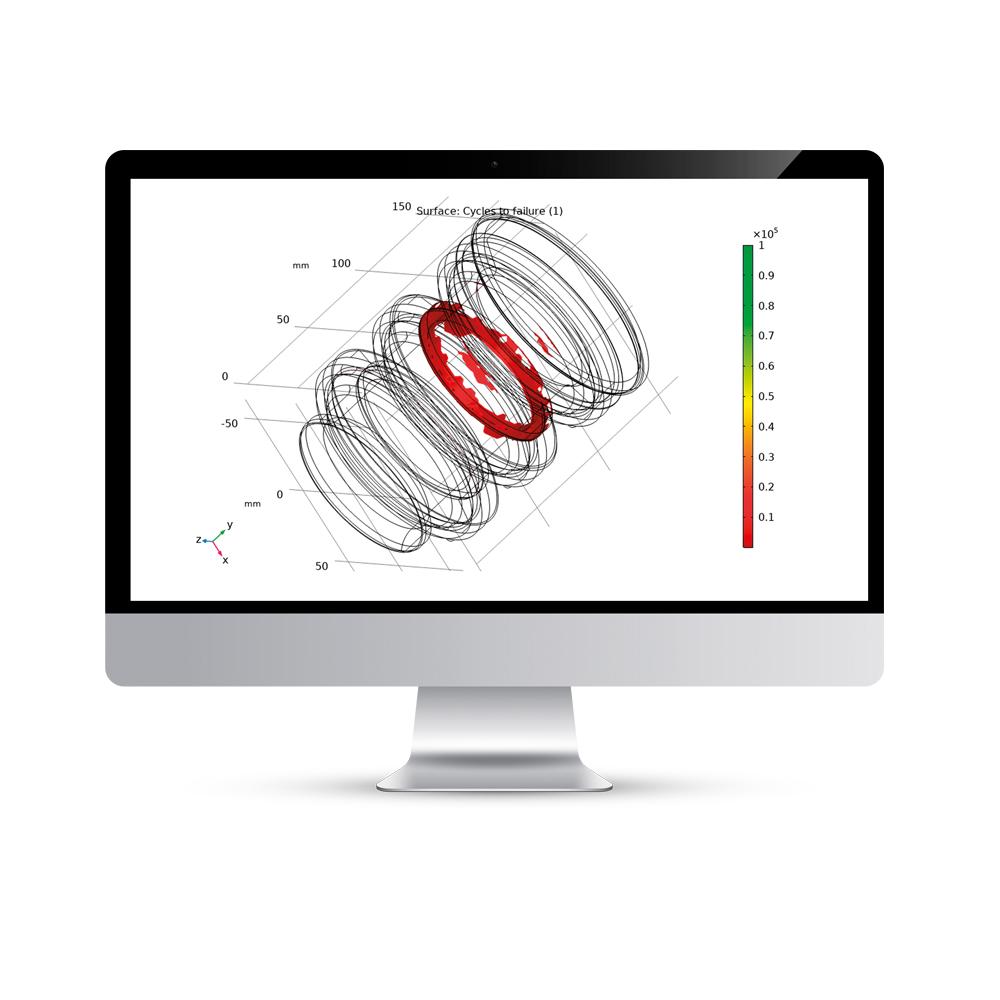

Modeling and numerical simulations: Calculation of flanged joints

Through High Performance Computer based simulation and parallel computer clusters we can run mathematical modeling and numerical simulations in dozens instead of thousands of hours.

The results are dynamic simulations from which optimal models can be obtained for elastic interaction and non-linear modeling that such complex mechanical systems experience.

The results are dynamic simulations from which optimal models can be obtained for the elastic interaction and nonlinear modeling experienced by these complex mechanical systems.

These models allow not only to optimize the tightening sequence and process, offering great time savings but also annihilate levels of uncertainty on the integrity of critical joints as part of our Safe Bolted Joints commitment.

From optimal flange to bolt rigidity ratios to Finite Element Analysis and complete bolted joint modeling and numerical simulations.

Diagnose and solutions

Real Root Cause Analysis (RRCA) added to our experience, allows our Tech Center to come with the most appropriate solution. From Design flaws to bolt load related problems that may be causing fatigue, thread striping, bolt yielding…

In many instances, we are contacted also during the design process, where we can predict potential bolt load problems offering alternatives that can warranty safe bolted joints. In other cases, we are presented with specific incidents or failures; our Tech Center will study flange to bolt rigidity factors, manufactechnical assistance turing and material configurations, load stability… and all other matters that may have

caused bolted joint integrity incidents, to come up with the best solutions.

Although many of these analysis, and solutions are achieved as a reactive methodology, the potential of our experience, knowledge and the resources of our Tech Center can, and should, be used as a Preventive Strategy.

MEET OUR ENGINEERS

The key to overcoming technical challenges in tightening lies in our ability to model, diagnose, and provide precise solutions.

Germán Rodríguez

Tech & Oper. Manager

Diego Esteban

Mechanical Design

Daniel Souto

Mechanical Design

Cristina Cendán

Mechanical Design

Daniel Area

Mechanical Design

Guillermo Saavedra

Mechanical Design

Xan Candal

Calculations & SQC

Pablo Bello

Engineering Support

Juan Andrés Matos

Technical Support

Iván Bellas

Technical Support

Daniel Dans

ICT Support

Jose Martínez

Firmware & Electronics

Javier Fernández

Firmware & Electronics

Daniel Cerdeira

Firmware & Electronics

Mikel Ortega

Firmware & Electronics

Cristian López

Firmware & Electronics

Juan Santos

Software Development

Marcos Fidalgo

Software Development

OTHER SERVICES

Repairs

We are experts in repair services and preventing future issues.

>>More info

Calibration

We handle pressure, load, and torque calibration for any industry.

>>More info

Ultrasonic

The best bolt load ultrasonic measurement service.

>>More info

Inspection

We conduct thorough inspections to ensure all fastenings are perfect.

>>More info

Fleet management

Comprehensive bolting tool fleet management service.

>>More info

DISCOVER THE SERVICES AND PRODUCTS FOR EACH INDUSTRY

Wind industry

Wind industry

Solar Photovoltaic Thermal Industry

Chemical and Petrochemical Industry

Civil Construction and Machinery

Pulp and Paper Industry

Shipbuilding Industry

Steel and Metallurgical Industry

Hydrogen industry

General industry

REQUEST MORE INFORMATION FROM OUR TECH CENTER

Contact us and we will advise you