FlangePilot: Asset Management software for flanged joints in petrochemical plants

+ Reduction of inspection costs

+ Increased productivity

+ Our purpose: Zero Incidents

ASME PCC-1

All our products and services are designed, manufactured, and executed in accordance with ISO 9001, ISO 14001, and ISO 45001 standards. Our procedures, calculations, and qualifications are all based on standards such as ASME, PVRC, PCC-1, Energy Institute, API, Fluid Sealing Association, EN 1951, Norsok, among others.

Request a trial version of FlangePilot from our experts

Improve efficiency and avoid errors or unnecessary shutdowns by recording tightenings in real time. Request a demo of our software

History of tightening and joints

All work carried out on the joint during its useful life is recorded, from opening to final closure.

Condition control and labeling

Easy identification of joints through the use of labels that allow us to know their status easily at any time.

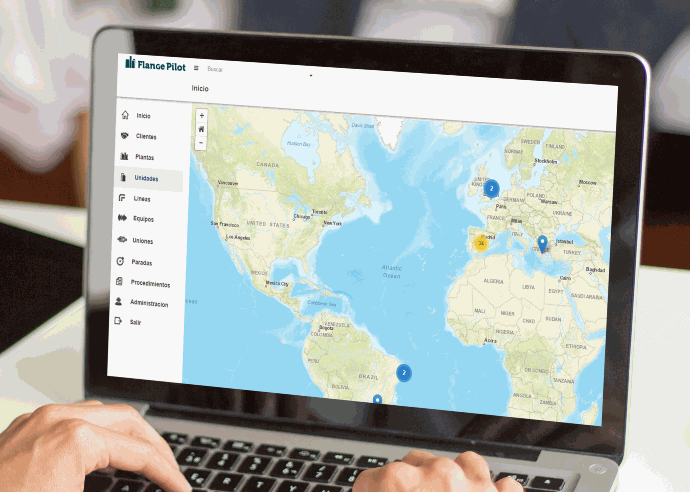

Portable, multi-user and multi-plant

By assigning roles, each user will have the appropriate permissions to carry out their work.

Real-time reports

FlangePilot® allows the generation of specific reports for each client, tailored to meet their particular needs.

FlangePilot®: Traceability and control of critical flanged joints in process and petrochemical plants

Safe joints in a plant are the backbone of preventing leaks, spills and potential catastrophic accidents. A single poorly tightened bolt, a defect in the sealing area of the joint or an incorrect material of an element that makes up the joint can lead to disastrous consequences and put the safety of people who work in our industry and its environment at risk.

CERTIFIED TIGHTENING ACCORDING TO ASME PCC-1

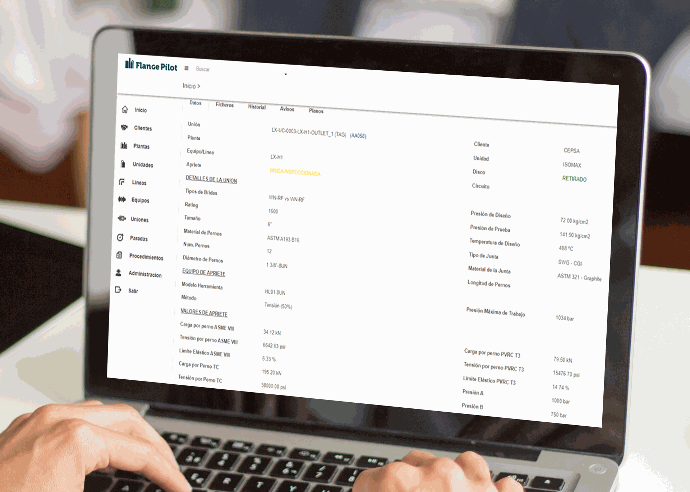

Our flanged joint integrity management system, FlangePilot®, allows us to know the status of each joint in real time by recording all interventions carried out, ensuring compliance with the most appropriate procedures for each case.

TRACEABILITY & DIGITALIZATION

With the implementation of FlangePilot®, our clients have all the information related to the work carried out in a critical joint throughout its useful life, as well as all the digitalized technical documentation necessary to be able to undertake the work correctly. and sure.

Saving time and costs

FlangePilot® allows you to optimize work completion times by providing total traceability and having all the necessary information at the click of a button. Costs are reduced by minimizing incidents resulting from incorrect tightening and reducing unplanned stops caused by leaks.

Tighten according to procedure

All critical joints registered in FlangePilot® have their specific calculation sheet and their opening, inspection and closing procedures associated with them in order to guarantee that the work is carried out correctly, ensuring tightness during their useful life.

Fully customizable

FlangePilot® adapts to the particularities of each client, allowing the management of multi-plant clients, users with different roles and needs, communication with 3D models, connection with ERP systems, etc.

OUR FEATURED TOOLS FOR THE OIL AND GAS INDUSTRY

Contact our expert technicians at FlangePilot®

We will advise you on the best option for your industry